Embracing technology for optimization is a necessary strategy for any manufacturing company looking to stay relevant and remain competitive. Manufacturers who invest in optimizing their operations benefit from increased efficiency, reduced downtime, and improved regulatory compliance.

“Keeping pace with the growth in smart manufacturing technologies is crucial for remaining competitive in today’s industry, particularly for the small and medium-sized businesses that make up so much of the manufacturing sector,” said Robert “Bob” Willig, SME Executive Director and CEO. “The benefits of being able to be nimble, reduce waste, and keep track of components throughout the production process are more than worth the investment in the tools and technology.”

Cody Bann, Director of Engineering at SmartSights, has spent the majority of his career helping manufacturers optimize. During his time at SmartSights, a company specializing in industrial alarm notification software, Bann has developed OT intelligence tools to inform manufacturers on the health and status of assets and operations and provided strategies for optimization.

“Providing the right information to the right people at the right time is critical to optimization,” Bann explains. “Industrial advancement has created this explosion of data at manufacturing plants, and utilizing the valuable insights from that data helps manufacturers streamline optimization and realize those benefits.”

Learn how technology, data, and real-time reporting intersect to drive optimization in present-day manufacturing facilities.

Driving Digitalization

Digitalization is inevitable for industrial factories to maintain relevance in an interconnected future. As manufacturers have adapted to this new reality, adoption of more advanced technologies has increased.

Not only do these technologies give companies a competitive edge, but they’re also helping to combat an ongoing issue in manufacturing: the worker shortage. The problem is so severe there are predictions of more than two million manufacturing jobs going unfilled by 2030.

Due to this, more organizations are embracing robotics to perform repetitive tasks with high precision. “They’re augmenting the human workforce and, in some cases, replacing roles,” Bann explains. “Robots don't mind that a task is monotonous and repetitive, so that's a big win for workers performing these tasks.”

Though robotics has its place in combating the labor issue, another technology manufacturers are turning to is alarm notification software. Digitalization enables smart alarm notification that relays the most important information to operators and allows for prioritization.

“Using smart sensors and monitoring software to network equipment into the industrial internet of things (IIoT) enables decision making based on what’s actually happening,” says Willig. “Being able to see problems before they happen and make adjustments to keep production lines running drives some real improvements in efficiency.”

Optimizing Operations with Technology

The focus on digitalization is driving more connected operations and leading many manufacturers to leverage smart technologies to enhance processes and optimize operations. Augmented reality (AR) and digital twins, for example, are advanced technologies used to improve operations. AR helps with situational awareness in manufacturing facilities and is used for training. Digital twin technology has the potential to optimize designs and processes.

Investing in things like training and process improvement is key to achieving optimization. However, technologies like AR and digital twins can be a daunting investment for some small- to medium-sized manufacturers. That’s why technologies with a lower barrier to entry – automation, alarm notification software, sensors – are more widely adopted.

These technologies not only make workers better at their jobs, but they can also foster collaboration and enable more informed decision making. Alarm notification software in particular can drive collaboration among workers.

“SmartSights remote notification software has a mobile platform that offers easy access to information and to peers. Workers have access to their phones anywhere, providing up-to-date information on unfolding conditions and constant contact with team members. The software lets teams collaborate and chat with each other in the context of an alarm,” describes Bann. “With the shifting workforce and aging workers, this mobile alarm notification allows companies to do more with fewer people. Operators that go on-site to make a repair can lean on the expertise of their team with this technology.”

Utilizing SCADA Systems

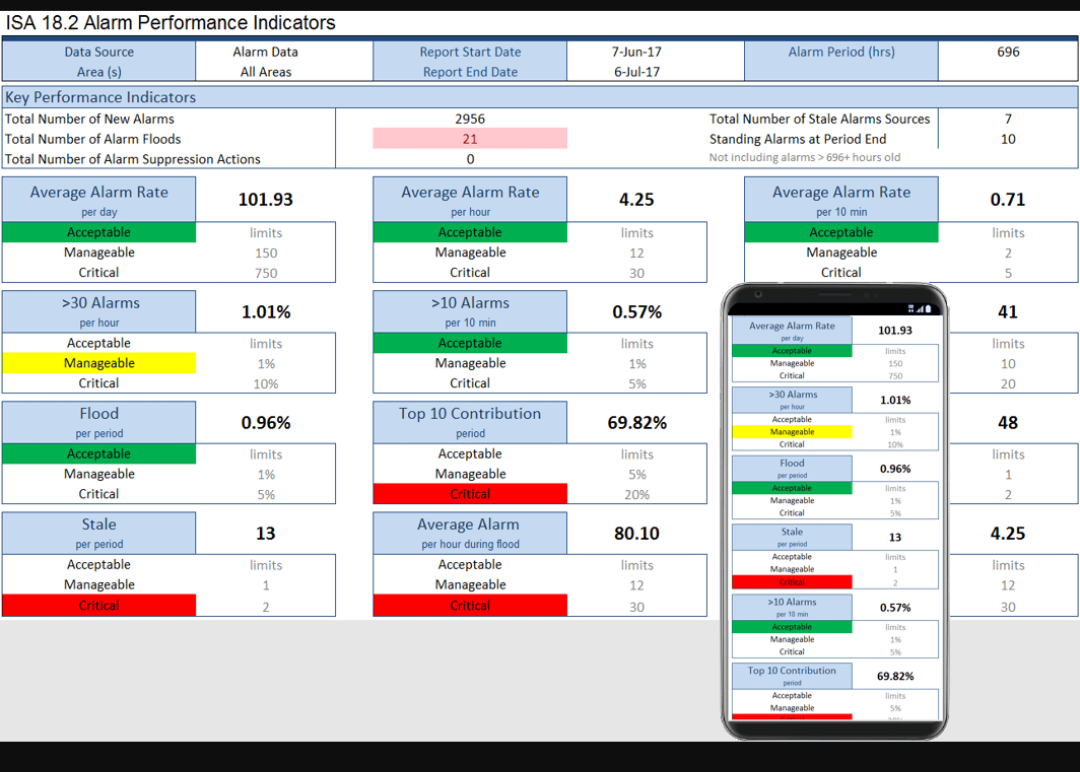

Another technology driving optimization within manufacturing facilities is Supervisory Control and Data Acquisition (SCADA) systems. These systems control, monitor, and analyze industrial assets and processes.

Utilizing SCADA systems allows manufacturers to gather data from industrial equipment, enabling better decision-making. But these systems can also take it a step further.

“Data in its raw form is difficult to do much with, so companies have to put that data into context,” emphasizes Bann. “A sensor might give you an updated value on a tank level, but it’s the SCADA system that extends that raw sensor value to provide meaningful information.”

The added data provided by SCADA systems enables manufacturers to make decisions that improve efficiency in operations and increase production speed. This equates to more parts produced in less time, helping manufacturers stick to production schedules and freeing them up to take on more work.

SCADA systems can also collect data from multiple sensors throughout a factory floor. Capturing all this data provides a holistic picture of asset performance, which the SCADA system relays in an easily digestible format for human workers.

In this way, SCADA systems are providing information transparency throughout facilities. This curated data offers insights into operational processes and production, and these insights drive better decisions towards a goal of optimizing operations.

The Role of Remote Alarm Notification Software

While SCADA systems monitor assets and report on conditions, it’s not always apparent when a problem or abnormality arises. To ensure issues are caught in a timely manner, manufacturers utilize remote alarm notification software.

According to Bann, this software relies on data from SCADA systems and is all about getting the right information to the right people at the right time, which, as stated previously, is necessary for effective optimization strategies.

“Alarm notification software helps manufacturers understand where their process is generating too many alarm conditions, so they can pinpoint the assets responsible for a disproportionate number of those alarms,” Bann explains. “This enables industrial companies to make better decisions about asset maintenance and replacement and even allows them to optimize their alarm definition, deciding that they should alarm later or closer to a real threshold.”

Bann describes some other opportunities for optimization as well with notification management software, which helps manufacturers understand which operators or technicians are most responsive and which ones may be receiving too many notifications.

“This software takes the alarms manufacturers have built inside their SCADA system and proactively alerts operators and technicians. This is particularly important with staffing constraints. Manufacturers have to make workers aware of issues arising in the plant, so they can focus their attentions on remitting those situations quickly. That's where alarm notification really shines,” Bann emphasizes.

It goes back to the idea of notifying the right people at the right time so facilities can operate more effectively, even with fewer workers. Alarm notification software enables continuous monitoring despite a lack of staff, which helps the workers dealing with alarm notifications to optimize their processes and keep things running smoothly.

“Despite having a smaller workforce, manufacturers can utilize the data from SCADA systems and alarm software to create escalation strategies, implement responses to unfolding alarm notification, manage personnel schedules, and customize alarm formats,” Bann states.

Data and Reporting

Another facet of alarm notification is just-in-time reporting. Reports can be updated and sent upon an alarm condition having occurred or a process event such as batch completion. These reports provide the data used to make informed decisions on optimization strategies.

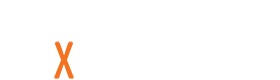

“Reporting software visualizes data and distills it into charts and tables that capture the key performance indicators and key predictive measurements that drive decision making. Data and reporting empower decision makers to identify bottlenecks and inefficiencies in real time,” Bann says.

Companies collect data from sensors, SCADA systems, and automated processes, for example, but then have to determine how to effectively analyze that data to optimize their operations. The real trick is to curate this data through automated, just-in-time reporting.

This reporting solution, which is provided by remote alarm notification and management software, contextualizes data, and enables manufacturers to identify anomalies, streamline regulatory compliance, strategize predictive maintenance schedules to minimize downtime, and more.

“Embracing data, analytics, and reporting allows manufacturers to position themselves for success, respond to a highly dynamic environment, and continuously optimize their operations,” Bann explains.

Achieving Optimization Through Continuous Improvement

All of the technology utilized by a manufacturing facility is implemented with the intention to improve operations. But optimization doesn’t start and end with new technology implementations.

“Optimization is not a one-off undertaking, it is a continuous process,” says Bann. “A plant is a dynamic system with ever-changing manufacturing needs. The steps a manufacturer took towards optimization yesterday may not have the same positive effects tomorrow.”

That’s why having a mindset of continuous improvement is so important. Manufacturers can leverage technology like automation and real-time alarms to increase productivity, improve efficiency, and reduce costs, but those initial benefits can be expanded through a focus on optimization and continuous improvement.

Manufacturing companies must track their changes and measure progress to see the impacts new technologies and processes have on their production performance. This is an ongoing process, and manufacturers must be willing to potentially change tactics to succeed. The openness to change and willingness to continually improve will help manufacturers on the path to optimize operations.

“Keeping up with the latest technologies and strategies for smart manufacturing can be challenging no matter how large or small your business is,” said Willig. “That’s why SME is continuing to support manufacturers with events like the Smart Manufacturing Experience, where we can use our expertise and connections to bring leaders in the space together to share their knowledge and demonstrate how to stay current to maximize success.”

If you’re a manufacturer interested in optimization and want to learn more about how remote alarm notification software and real-time reporting can advance your operations, reach out to SmartSights. And if you’re also interested in the benefits of other smart technologies, learn more by attending Smart Manufacturing Experience.

Bio:

Cody P. Bann

Cody P. Bann serves as Director of Engineering for SmartSights, having 16 years of software development experience with the Austin-based company. He holds a Master of Science in Computer Science from The University of Texas at Austin and a BA in Computer Science from Boston University.

Cody P. Bann serves as Director of Engineering for SmartSights, having 16 years of software development experience with the Austin-based company. He holds a Master of Science in Computer Science from The University of Texas at Austin and a BA in Computer Science from Boston University.